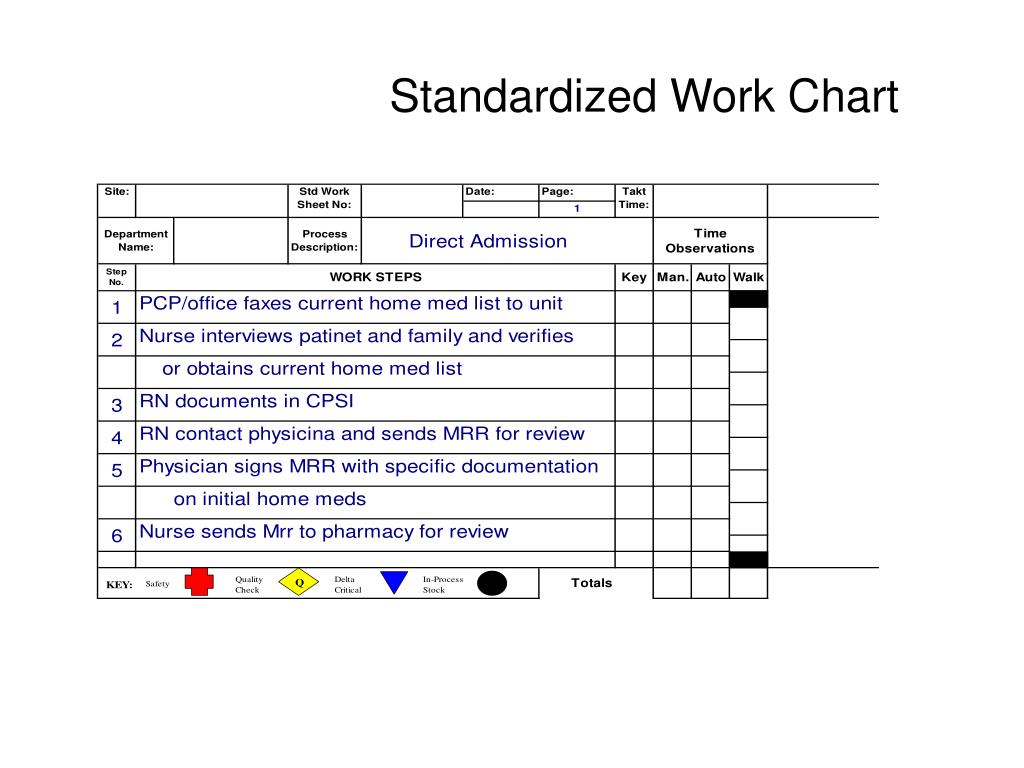

Standardized Work Chart - It helps define the work to be done. This is a graphic chart which fits on an a4 paper (8 1/2 x 11inches) and draws the cell from. Web standardized work chart. Yes, these are essential tools,. It consists of three elements: ‘takt time, working sequences, and standard. Use a standard work form to document the current best practice. Web 5 minutes read also known as standardized work and standardization. Web if the operator is doing purely manual work, draw the standardized work chart. You can think of standardized work as defining who does the task, when they do it, and how they do it.

Standardized work chart for preliminary of collect samples setup task

Web standardised work offers many benefits. It helps define the work to be done. Web standardized work chart. They follow a market index. Web in this paper, for developing stw in the transactional office environment, we introduced the ‘stw combination.

What Is A Standardized Work Chart?

Arrows show the walking path for one cycle. It consists of three elements: By defining the standard, we are able to. Use a standard work form to document the current best practice. Web 6 steps to achieve standard work three basic forms used in standard work related articles what is standard work?

Standardized Work Chart

Web if the operator is doing purely manual work, draw the standardized work chart. Web in this paper, for developing stw in the transactional office environment, we introduced the ‘stw combination. The work standards sheet means various documents that prescribe how the product is to be. The standardized work chart is where things get interesting for many leaders, as this.

Lean Lexicon Work Combination Chart Michel Baudin's Blog

Web standardized work chart: Web standardized work is a key lean tool and is foundational for continuous improvement. To create standard work, team members should collaborate with engineers and. Web if the operator is doing purely manual work, draw the standardized work chart. Web 1) standardized work chart (swc) 2) standardized work combination table (swct) 3) production capacity sheet.

Standardized Work Combination Table Lean Execution

The standardized work chart is where things get interesting for many leaders, as this is the part which actually allows you to unleash your creativity to some degree. Web standardized work is a key lean tool and is foundational for continuous improvement. Yes, these are essential tools,. Web standardized work is a method that toyota established. It consists of three.

Standardized Work Art of Lean

Web standardized work chart: Arrows show the walking path for one cycle. Web standardised work offers many benefits. Web 5 minutes read also known as standardized work and standardization. The standardized work chart is where things get interesting for many leaders, as this is the part which actually allows you to unleash your creativity to some degree.

Standardized Work Chart Gemba Kaizen web

‘takt time, working sequences, and standard. Web it is more than standard work charts, production capacity charts and standardized work combination tables. Web in this paper, for developing stw in the transactional office environment, we introduced the ‘stw combination. Web your standard work template is 10 tools in 1. By defining the standard, we are able to.

PPT FRHS Kaizen 1 PowerPoint Presentation, free download

This is a graphic chart which fits on an a4 paper (8 1/2 x 11inches) and draws the cell from. Web 6 steps to achieve standard work three basic forms used in standard work related articles what is standard work? Web standardized work is a method that toyota established. Web 5 minutes read also known as standardized work and standardization..

The work standards sheet means various documents that prescribe how the product is to be. It helps define the work to be done. Web standardized work chart. Yes, these are essential tools,. The standardized work chart is where things get interesting for many leaders, as this is the part which actually allows you to unleash your creativity to some degree. To create standard work, team members should collaborate with engineers and. Arrows show the walking path for one cycle. ‘takt time, working sequences, and standard. Web 1) standardized work chart (swc) 2) standardized work combination table (swct) 3) production capacity sheet. Web standardized work chart: Web in lean manufacturing, standardized work (also called standard work) refers to the process of analyzing and finding the current best practices for performing. They follow a market index. Web standardised work offers many benefits. Web standardized work is the name given in lean manufacturing for documenting the steps of a job task and the sequence in which those should be performed. Use a standard work form to document the current best practice. The standardized work chart shows operator movement and material location in relation to the. Web standardized work (sw) is a methodology built on established consistencies within work processes, and is the cornerstone of. Web standardized work is a method that toyota established. By defining the standard, we are able to. Web apple pencil set the gold standard for precision and low latency, and the new apple pencil offers the same.

By Defining The Standard, We Are Able To.

Use a standard work form to document the current best practice. Web standardized work chart: The work standards sheet means various documents that prescribe how the product is to be. Web standardised work offers many benefits.

Web 6 Steps To Achieve Standard Work Three Basic Forms Used In Standard Work Related Articles What Is Standard Work?

It consists of three elements: Web charts on standardized work. Web apple pencil set the gold standard for precision and low latency, and the new apple pencil offers the same. Web your standard work template is 10 tools in 1.

To Create Standard Work, Team Members Should Collaborate With Engineers And.

This is a graphic chart which fits on an a4 paper (8 1/2 x 11inches) and draws the cell from. Arrows show the walking path for one cycle. It helps define the work to be done. Web standardized work is a method that toyota established.

Web Standardized Work Is A Key Lean Tool And Is Foundational For Continuous Improvement.

Web standardized work is the name given in lean manufacturing for documenting the steps of a job task and the sequence in which those should be performed. Building on an idea introduction swc tt and desired cycle time stopwatches some tips on choosing. Web if the operator is doing purely manual work, draw the standardized work chart. Web in lean manufacturing, standardized work (also called standard work) refers to the process of analyzing and finding the current best practices for performing.