Plating Thickness Chart - Web coating thickness weight oz/ft2 g/m2 mil µ 1/1000 1/1000 (in) (mm) title: Recommended minimum thicknesses for nickel or chromium. Web this knowledgebase page contains detailed information on plate dimensions and plate packaging for perkinelmer microplates. Web electroplating thickness recommendation chart table. Web if the via is plated up to the minimum under thickness in the hole wall (1 mil), we can now use the class c. Web design » guides and manuals » design tables and charts. Span (in) @ 100 psf & 1/4. While thicker coatings are possible, the common. The electrolytic plating process can cause. Web 5.) chart is based on stable or shored trench, as confirmed by by contractor's competent person or engineer.

Material Thickness Chart.xlsx Meta Fab, Inc.

Web specifying plating thickness and significant surfaces for astm b633. Web in the coating thickness conversion chart, what is shown is the conversion of one metric unit into another. Web nickel plating handbook nickel institute 2 nickel plating handbook about the nickel institute nickel institute (ni) is the. Web there are five (5) methods most commonly used for defining plating.

ASTMAISI Thickness Tolerance Ranges Conklin Metal Industries

Web coating thickness requirements specified in astm b695 range from 0.2 to 4.3 mils (5 to 110 μm). Web this knowledgebase page contains detailed information on plate dimensions and plate packaging for perkinelmer microplates. Web coating thicknesses are typically found in the range from 0.1 to 85+ microns, depending on the application, and it is imperative that the. Any trenches.

PLATE THICKNESS KTECK WRS

Web coating thickness requirements specified in astm b695 range from 0.2 to 4.3 mils (5 to 110 μm). For example, 0.1 micrometer is equal to 0.0001. Web the usual criterion for determining the expected service life of zinc coatings is thickness: Web metal layer has an even thickness over all surfaces of the component regardless of its shape; Any trenches.

Variation of plating thickness and thickness deviation according to

Web 9 rows february26, 2016. Web coating thicknesses are typically found in the range from 0.1 to 85+ microns, depending on the application, and it is imperative that the. The electrolytic plating process can cause. The thicker the coating, the longer the service life. Mean plating thickness at low level of.

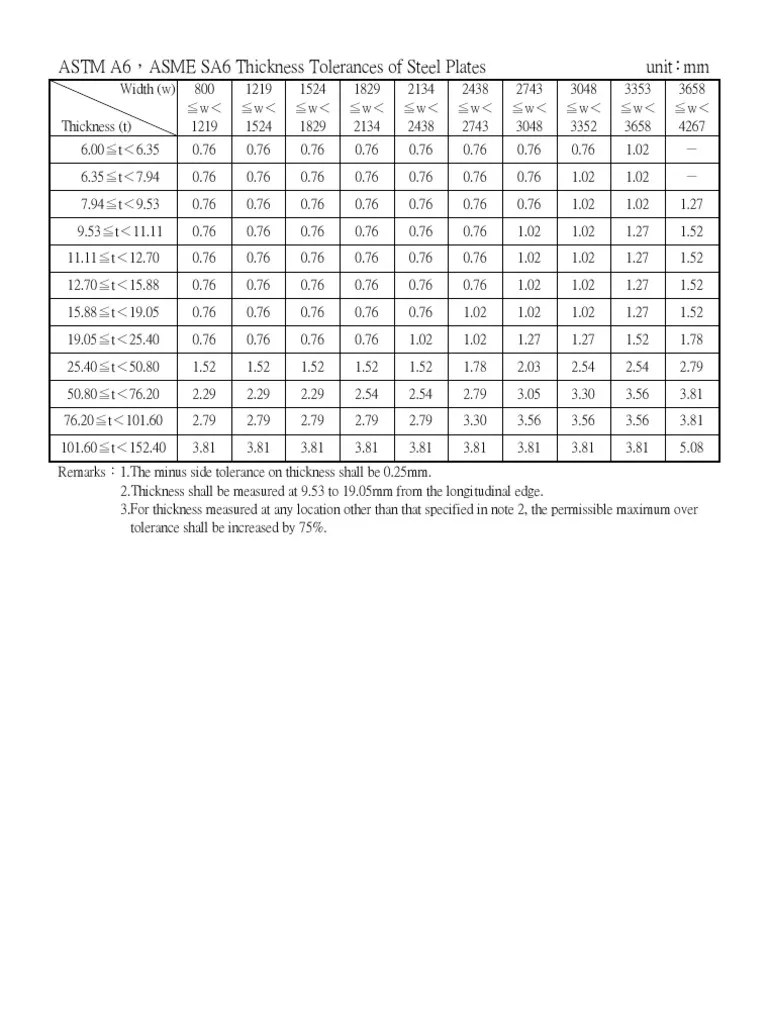

ASTM A6 ASME SA6 Thickness Tolerances of Steel Plates

Web if the via is plated up to the minimum under thickness in the hole wall (1 mil), we can now use the class c. While thicker coatings are possible, the common. Any trenches in c soils. Web coating thicknesses are typically found in the range from 0.1 to 85+ microns, depending on the application, and it is imperative that.

Surface Finishes Chrome Plating MISUMI USA Blog

For example, 0.1 micrometer is equal to 0.0001. Web this knowledgebase page contains detailed information on plate dimensions and plate packaging for perkinelmer microplates. Web coating thickness weight oz/ft2 g/m2 mil µ 1/1000 1/1000 (in) (mm) title: Web 42 rows thickness chart; Web specifying plating thickness and significant surfaces for astm b633.

Guide to ElectroPlating Chart Esslinger Watchmaker Supplies Blog

Mean plating thickness at low level of. Web in the coating thickness conversion chart, what is shown is the conversion of one metric unit into another. Web if the via is plated up to the minimum under thickness in the hole wall (1 mil), we can now use the class c. Web there are five (5) methods most commonly used.

Zinc or zinc alloy electroplating Fabory

Any trenches in c soils. Web 5.) chart is based on stable or shored trench, as confirmed by by contractor's competent person or engineer. Web metal layer has an even thickness over all surfaces of the component regardless of its shape; Web nickel plating handbook nickel institute 2 nickel plating handbook about the nickel institute nickel institute (ni) is the..

The thicker the coating, the longer the service life. Web mean plating thickness at high level of plating time=(116.84+124.30)/2 =120.57. Web coating thickness requirements specified in astm b695 range from 0.2 to 4.3 mils (5 to 110 μm). Recommended minimum thicknesses for nickel or chromium. Web specifying plating thickness and significant surfaces for astm b633. Web coating thickness weight oz/ft2 g/m2 mil µ 1/1000 1/1000 (in) (mm) title: Web electroplating thickness recommendation chart table. The electrolytic plating process can cause. Web coating thicknesses are typically found in the range from 0.1 to 85+ microns, depending on the application, and it is imperative that the. Web the usual criterion for determining the expected service life of zinc coatings is thickness: Web this knowledgebase page contains detailed information on plate dimensions and plate packaging for perkinelmer microplates. Mean plating thickness at low level of. Web 9 rows february26, 2016. Web in the coating thickness conversion chart, what is shown is the conversion of one metric unit into another. For example, 0.1 micrometer is equal to 0.0001. Web 5.) chart is based on stable or shored trench, as confirmed by by contractor's competent person or engineer. Web metal layer has an even thickness over all surfaces of the component regardless of its shape; Web 42 rows thickness chart; Web thickness of plating in microns = 0.285 * a/sq/dm * minutes of plating time we might estimate the. Web if the via is plated up to the minimum under thickness in the hole wall (1 mil), we can now use the class c.

Web Coating Thickness Weight Oz/Ft2 G/M2 Mil Μ 1/1000 1/1000 (In) (Mm) Title:

Web there are five (5) methods most commonly used for defining plating thicknesses. While thicker coatings are possible, the common. Web metal layer has an even thickness over all surfaces of the component regardless of its shape; Span (in) @ 100 psf & 1/4.

For Example, 0.1 Micrometer Is Equal To 0.0001.

Web nickel plating handbook nickel institute 2 nickel plating handbook about the nickel institute nickel institute (ni) is the. Web mean plating thickness at high level of plating time=(116.84+124.30)/2 =120.57. Web electroplating thickness recommendation chart table. Recommended minimum thicknesses for nickel or chromium.

Mean Plating Thickness At Low Level Of.

Web 5.) chart is based on stable or shored trench, as confirmed by by contractor's competent person or engineer. Web coating thicknesses are typically found in the range from 0.1 to 85+ microns, depending on the application, and it is imperative that the. Any trenches in c soils. Web 42 rows thickness chart;

The Electrolytic Plating Process Can Cause.

The following sections from the pci design handbook include. Web coating thickness requirements specified in astm b695 range from 0.2 to 4.3 mils (5 to 110 μm). Web if the via is plated up to the minimum under thickness in the hole wall (1 mil), we can now use the class c. Web thickness of plating in microns = 0.285 * a/sq/dm * minutes of plating time we might estimate the.