Pipe Bend Radius Chart - If a fitting or mechanical connection is present in the. Web what is the minimum bend radius for each size? Web use the following equation to calculate the pipe bend radius (r): The distance from the center of curvature to the. Web using the image below, you can see how the radius of a bend has a significant impact on the resulting part. When choosing a die, factors that will affect the clr you choose include the material type and grade to be bent, wall thickness, the od, the application or design of the end product, and overall appearance required. The tightest clr that you can bend is 2 (depending on your material), using the. A basic rule of thumb is any 10’ section of any of the diameters can make a 180. R=2d, 2.5d, 3d bend, 5d bend, 6d, 8d, 10d, 12d bend degree range : Web fittings and mechanical connections are rigid compared to the pipe.

Tubing bending chart plmultra

The distance from the center of curvature to the. We also manufacture custom bends to suit our. R = a(od) in the. When choosing a die, factors that will affect the clr you choose include the material type and grade to be bent, wall thickness, the od, the application or design of the end product, and overall appearance required. Web.

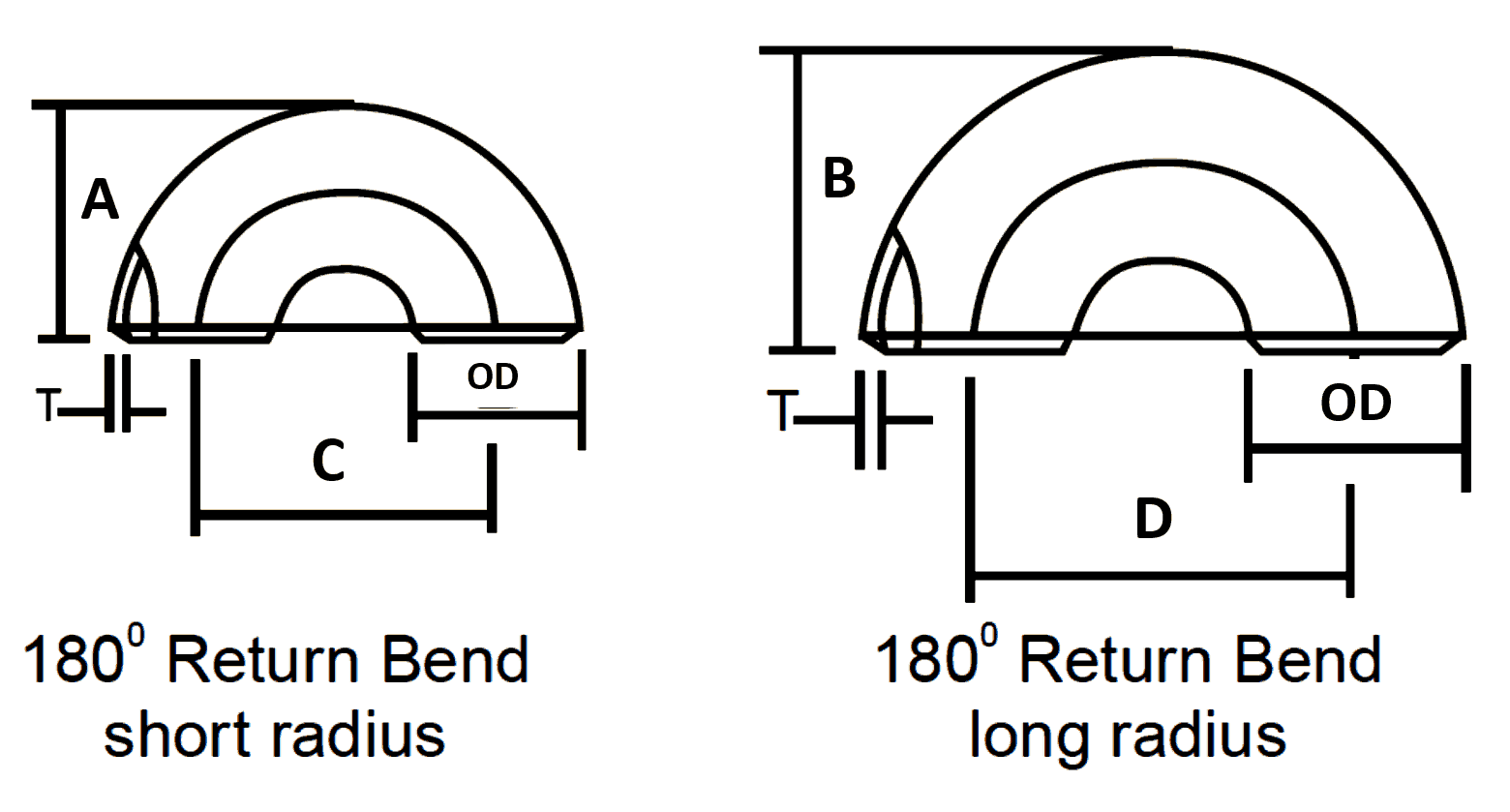

Pipe Bends & Return Dimensions in mm (Long & Short Radius)

Web pipe size radius r 90 degree bends 45 degree bends g a b c d e f ½” 1 ½” 5 ½” 7” 4 5/8” 6” 5 ¼” 6 1/8” ¾” 1 ½” 5 ½” 7” 4. R = c/2(pi) where pi = 3.14 for example, if you. Web the minimum bending radius for 300 mm (0.3 m) pe.

Duplex Steel Pipe Bends Dynamic & Fittings

When choosing a die, factors that will affect the clr you choose include the material type and grade to be bent, wall thickness, the od, the application or design of the end product, and overall appearance required. Because of the pipe's ability to bend,. Web pipe size radius r 90 degree bends 45 degree bends g a b c d.

Copper tube bending radius chart nomghost

Web 5 types of tube bending 10 the two main types of roll bending machine 11 is draw bending better than roll bending 12 tube. Web use the following equation to calculate the pipe bend radius (r): What is a tube bending radius chart? Web actuated drive mechanism which enables an operator to make bends up to 180° in one.

Technical Information MaxPro Technologies Inc.

Web pipe bends are classified according to the centerline radius (clr) of the bend as a ratio to the nominal pipe diameter. What is a tube bending radius chart? Web after you’ve selected the appropriate die for bending your pipe, based on the pipe’s outside diameter and wall thickness, you should be able to find the radius. Web general details.

Understanding The Pipe Offset Chart

Web pipe bends are classified according to the centerline radius (clr) of the bend as a ratio to the nominal pipe diameter. Web actuated drive mechanism which enables an operator to make bends up to 180° in one continuous smooth operation on tubing up. Web general details technical info dwg & spec related products steel pipe bend is a pipe.

Tube bending radius chart paseroll

Web after you’ve selected the appropriate die for bending your pipe, based on the pipe’s outside diameter and wall thickness, you should be able to find the radius. Web using the image below, you can see how the radius of a bend has a significant impact on the resulting part. This table is created to help the estimator to calculate.

Tube bending chart bopqewisconsin

Web after you’ve selected the appropriate die for bending your pipe, based on the pipe’s outside diameter and wall thickness, you should be able to find the radius. Web using the image below, you can see how the radius of a bend has a significant impact on the resulting part. Web the minimum bending radius for 300 mm (0.3 m).

Web 3d & 5d pipe bends the following charts show dimensions for our standard range of 3d and 5d bends. The arc of the bend itself, usually taken at the centerline. Web pipe bends are classified according to the centerline radius (clr) of the bend as a ratio to the nominal pipe diameter. Web fittings and mechanical connections are rigid compared to the pipe. When choosing a die, factors that will affect the clr you choose include the material type and grade to be bent, wall thickness, the od, the application or design of the end product, and overall appearance required. Because of the pipe's ability to bend,. Web pe pipes can be cold bent to a radius of 25 to 30 times the od of the pipe depending on its sdr. R=2d, 2.5d, 3d bend, 5d bend, 6d, 8d, 10d, 12d bend degree range : Web 5 types of tube bending 10 the two main types of roll bending machine 11 is draw bending better than roll bending 12 tube. If a fitting or mechanical connection is present in the. Web use the following equation to calculate the pipe bend radius (r): This table is created to help the estimator to calculate the inside. What is a tube bending radius chart? Web after you’ve selected the appropriate die for bending your pipe, based on the pipe’s outside diameter and wall thickness, you should be able to find the radius. R = a(od) in the. 45 degree, 60 degree, 90 degree and. The swagelok hand tube bender bends 1/8, 1/4, 5/16, 3/8, and 1/2 in., and 3, 6, 8, 10, and 12 mm outside diameter tubing. Web general details technical info dwg & spec related products steel pipe bend is a pipe fittings which used to change direction of. R = c/2(pi) where pi = 3.14 for example, if you. The tightest clr that you can bend is 2 (depending on your material), using the.

A Tube Bending Radius Chart, In This Example, Shows The.

Web the minimum bending radius for 300 mm (0.3 m) pe pipe during installation can be estimated to rmin = 30 (0.3 m) = 9 m radius and angle vs. Web what is the minimum bend radius for each size? Web pipe bends are classified according to the centerline radius (clr) of the bend as a ratio to the nominal pipe diameter. Web 5 types of tube bending 10 the two main types of roll bending machine 11 is draw bending better than roll bending 12 tube.

Web 3D & 5D Pipe Bends The Following Charts Show Dimensions For Our Standard Range Of 3D And 5D Bends.

Web actuated drive mechanism which enables an operator to make bends up to 180° in one continuous smooth operation on tubing up. R = a(od) in the. We also manufacture custom bends to suit our. The arc of the bend itself, usually taken at the centerline.

Web Pe Pipes Can Be Cold Bent To A Radius Of 25 To 30 Times The Od Of The Pipe Depending On Its Sdr.

Web the minimum bend radius for hdpe pipe can be calculated using the following equation: Web using the image below, you can see how the radius of a bend has a significant impact on the resulting part. Web fittings and mechanical connections are rigid compared to the pipe. When choosing a die, factors that will affect the clr you choose include the material type and grade to be bent, wall thickness, the od, the application or design of the end product, and overall appearance required.

The Tightest Clr That You Can Bend Is 2 (Depending On Your Material), Using The.

Web general details technical info dwg & spec related products steel pipe bend is a pipe fittings which used to change direction of. 45 degree, 60 degree, 90 degree and. If a fitting or mechanical connection is present in the. Because of the pipe's ability to bend,.